Unlock the full potential of your projects with BIMDeX’s tailored consulting services. From seamless CAD conversions to advanced BIM automation and modeling, we empower your team to work smarter, faster, and more collaboratively. Let's build a future-ready workflow together!

At BIMDeX, we specialize in bridging the gaps between design, technology, and execution. Our suite of consulting services is designed to simplify complex workflows, enhance collaboration, and ensure accuracy in every phase of your project. Whether you're looking to convert CAD files, create detailed BIM models, or streamline processes with automation, our expertise ensures you achieve your project goals efficiently and effectively.

With a focus on innovation and precision, BIMDeX provides end-to-end solutions that cater to diverse industry needs. Explore how our services can help you transform your ideas into actionable results while optimizing productivity and delivering exceptional outcomes.

Development of parametric models for doors, windows, furniture, wall decorations, partitions, ceilings, floors, louvers, grills, stairs, and more.

Creation of models for beams, columns, joints, trusses, decks, applicable to steel, wood, concrete, and RCC structures.

Design of HVAC ducts and equipment, switchboards, lighting fixtures, plumbing fixtures, toilet fixtures, water pipes, cables, trays, among others.

Modeling of plant room components such as compressors, overhead tanks, pumps, etc.

Developing customizable BIM components and objects for standardized design and seamless integration within the model.

Experience seamless 3D CAD data conversion and enhance your design efficiency.

Schedule a web meeting with our team to discuss your specific requirements and objectives.

We'll provide a tailored pricing plan based on your anticipated number of conversions per month or year.

Formalize our partnership by signing the SAAS agreement and completing the payment process.

Benefit from our 24/5 email and phone support as we handle your model conversions with care.

Securely upload your models for conversion into native BIM formats by our expert team.

Obtain your accurately converted models, ready to impress your clients with native BIM files.

Our BIM automation services offer customized solutions that automate the tiresome and repetitive modeling activities in your projects. We are driven by a relentless pursuit of excellence and commitment, transforming your projects to embrace efficiency and precision.

Experience seamless 3D CAD data conversion and enhance your design efficiency.

BIM Modeling

BIM Modeling

Our architectural, structural, and MEPF (Mechanical, Electrical, Plumbing, and Fire Protection) modeling services empower clients to leverage BIM for enhanced efficiency and reduced project risks.

Shop Drawings

Shop Drawings

We produce precise shop drawings for contractors, manufacturers, and suppliers, ensuring clarity and adherence to industry standards.

Level of Development (LOD)

Level of Development (LOD)

Our team delivers models across various LOD stages, including LOD 100, 200, 300, 400, and 500, following internationally recognized standards.

Point Cloud to BIM

Point Cloud to BIM

We convert laser scans into detailed 3D models, capturing all dimensions and intricacies, accompanied by shop drawings at various LODs.

Successfully executed projects across the United States, Asia Pacific, and the Middle East.

Proficient in Revit, MicroStation, AutoCAD, Inventor, Creo, SolidWorks, and more.

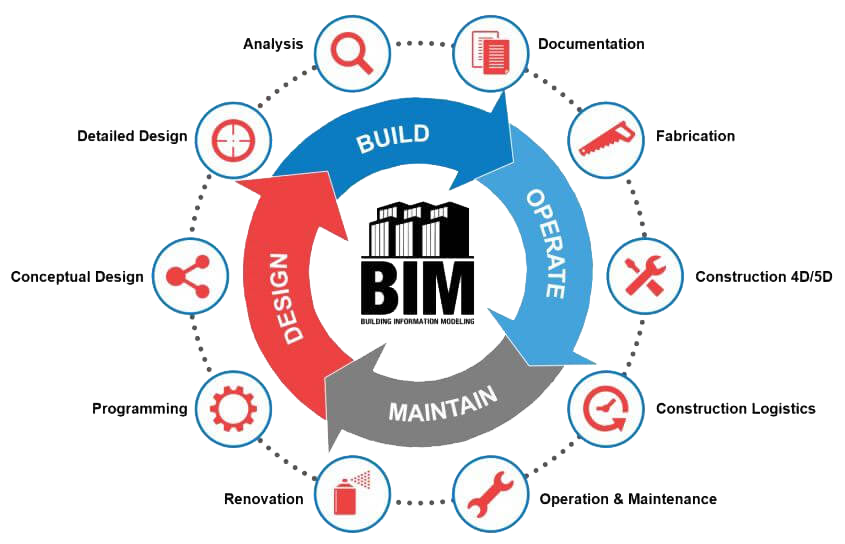

Offering services from design and analysis to construction documentation and facilities management.